Get Your Own ‘Skilled Operator’

Card After You Pass the Course

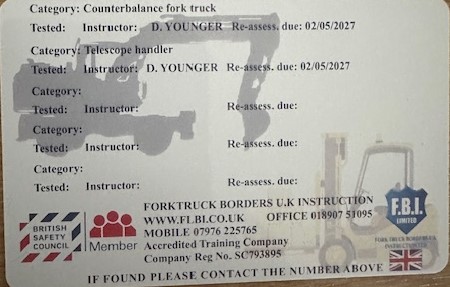

FORK TRUCK BORDERS INSTRUCTION UK LTD (FLBI) issues skilled operator cards to all candidates who pass their course.

Skilled operator cards are valid on ALL sites in the UK as we work to the guidelines (ACOP L117 + Loler Puwer & HASAWA regs).

FORK TRUCK BORDERS INSTRUCTION UK LTD have over 20 years’ experience in the training industry and have trained over 10,000 operators.

It is worth pointing out that FORK TRUCK BORDERS INSTRUCTION UK LTD (FLBI), as an experienced training company, adheres to all the legal information listed on this page.

Simple guide to the

Lifting Operations and Lifting

Equipment Regulations 1998 – Lifting

Introduction

This guide provides information about the legal requirements of the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) which came into force on 5 December 1998.

It gives a general indication of some of the main requirements of the Regulations. However, it is important that you refer to the Regulations and accompanying Approved Code of Practice to familiarise yourself fully with your duties (see Further information at the back of the document).

What is LOLER?

In the main, LOLER replaced existing legal requirements relating to the use of lifting equipment, for example the Construction (Lifting Operations) Regulations 1961, the Docks Regulations 1988 and the Lifting Plant and Equipment (Records of Test and Examination etc) Regulations 1992. Many aspects of LOLER should therefore be familiar to you.

The Regulations aim to reduce risks to people’s health and safety from lifting equipment provided for use at work. In addition to the requirements of LOLER, lifting equipment is also subject to the requirements of the Provision and Use of Work Equipment Regulations 1998 (PUWER), see Further information.

What does LOLER do?

Generally, the Regulations require that lifting equipment provided for use at work is:

– strong and stable enough for the particular use and marked to indicate safe working loads;

– positioned and installed to minimise any risks;

– used safely, ie the work is planned, organised and performed by competent people; and

– subject to ongoing thorough examination and, where appropriate, inspection by competent people.

What equipment is covered by the Regulations?

Lifting equipment includes any equipment used at work for lifting or lowering loads, including attachments used for anchoring, fixing or supporting it. The Regulations cover a wide range of equipment including, cranes, fork-lift trucks, lifts, hoists, mobile elevating work platforms, and vehicle inspection platform hoists. The definition also includes lifting accessories such as chains, slings, eyebolts etc. LOLER does not apply to escalators, these are covered by more specific legislation, ie the Workplace (Health, Safety and Welfare) Regulations 1992.

If you allow employees to provide their own lifting equipment, then this too is covered by the Regulations.

Do the Regulations apply to me?

If you are an employer or self-employed person providing lifting equipment for use at work, or you have control of the use of lifting equipment, then the Regulations will apply to you. They do not apply if you provide equipment to be used primarily by members of the public, for example lifts in a shopping centre. However, such circumstances are covered by the Health and Safety at Work etc Act 1974 (HSW Act).

While your employees do not have duties under LOLER, they do have general duties under the HSW Act and the Management of Health and Safety at Work Regulations 1999 (MHSWR), for example to take reasonable care of themselves and others who may be affected by their actions and to co-operate with others.

The Regulations cover places where the HSW Act applies – these include factories, offshore installations, agricultural premises, offices, shops, hospitals, hotels, places of entertainment etc.

What do the Regulations require me to do?

You need to ensure that in using any lifting equipment the requirements of LOLER are met.

For example, you should ensure that all lifting equipment is:

– sufficiently strong, stable and suitable for the proposed use. Similarly, the load and anything attached (eg timber pallets, lifting points) must be suitable;

– positioned or installed to prevent the risk of injury, eg from the equipment or the load falling or striking people;

– visibly marked with any appropriate information to be taken into account for its safe use, eg safe working loads. Accessories, eg slings, clamps etc, should be similarly marked. Additionally, you must ensure that:

– lifting operations are planned, supervised and carried out in a safe manner by people who are competent;

– where equipment is used for lifting people it is marked accordingly, and it should be safe for such a purpose, eg all necessary precautions have been taken to eliminate or reduce any risk;

– where appropriate, before lifting equipment (including accessories) is used for the first time, it is thoroughly examined. Lifting equipment may need to be thoroughly examined in use at periods specified in the Regulations (ie at least six-monthly for accessories and equipment used for lifting people and, at a minimum, annually for all other equipment) or at intervals laid down in an examination scheme drawn up by a competent person. All examination work should be performed by a competent person; and

– following a thorough examination or inspection of any lifting equipment, a report is submitted by the competent person to the employer to take the appropriate action. Other more specific legislation, for example the Personal Protective Equipment at Work Regulations 1992, may also apply. Under these particular Regulations there may be a need to provide a safety harness for rope access work during activities such as window cleaning.

How are the Regulations enforced?

Health and safety inspectors enforce the Regulations. If you have duties under LOLER you will be given time to assimilate the new requirements. However, where there are serious risks, or the requirements are not new, inspectors will be prepared to take firm enforcement action.

Simple guide to the Provision and

Use of Work Equipment (PUWER)

Introduction

This guide provides information about the legal requirements of the Provision and Use of Work Equipment Regulations 1998 (PUWER) which came into force on 5 December 1998. It gives a general indication of some of the main requirements of the Regulations. However, it is important that you refer to the Regulations and accompanying Approved Code of Practice to familiarise yourself fully with your duties (see Further information at the back of the leaflet).

What is PUWER?

PUWER replaces the Provision and Use of Work Equipment Regulations 1992 and carries forward these existing requirements with a few changes and additions, for example the inspection of work equipment and specific new requirements for mobile work equipment. Many aspects of PUWER should therefore be familiar to you. The Regulations require risks to people’s health and safety, from equipment that they use at work, to be prevented or controlled. In addition to the requirements of PUWER, lifting equipment is also subject to the requirements of the Lifting Operations and Lifting Equipment Regulations 1998 (see Further information).

What does PUWER do?

In general terms, the Regulations require that equipment provided for use at work is:

– suitable for the intended use;

– safe for use, maintained in a safe condition and, in certain circumstances, inspected to ensure this remains the case;

– used only by people who have received adequate information, instruction and training; and

– accompanied by suitable safety measures, eg protective devices, markings, warnings.

What equipment is covered by the Regulations?

Generally, ANY EQUIPMENT which is USED BY AN EMPLOYEE AT WORK is covered, for example hammers, knives, ladders, drilling machines, power presses, circular saws, photocopiers, lifting equipment (including lifts), dumper trucks and motor vehicles. Similarly, if you allow employees to provide their own equipment, it too will be covered by PUWER and you will need to make sure it complies.

Work equipment must meet ALL the requirements of the Regulations from 5 December 1998. However, requirements relating to certain aspects of mobile work equipment (see below) DO NOT apply to such equipment (provided for use in the business before 5 December 1998) until 5 December 2002. HSE information sheet MISC156 should be read if you use hired mobile work equipment, see Further information.

Examples of uses of equipment which are covered by the Regulations include starting or stopping the equipment, repairing, modifying, maintaining, servicing, cleaning and transporting.

Do the Regulations apply to me?

If you are an employer or self-employed person and you provide equipment for use at work, or if you have control of the use of equipment, then the Regulations will apply to you.

They DO NOT apply to equipment used by the public, for example compressed air equipment used in a garage forecourt. However, such circumstances are covered by the Health and Safety at Work etc Act 1974 (HSW Act). While your employees DO NOT have duties under PUWER, they do have general duties under the HSW Act and the Management of Health and Safety at Work Regulations 1992 (MHSWR), for example to take reasonable care of themselves and others who may be affected by their actions, and to co-operate with others.

The Regulations cover places where the HSW Act applies – these include factories, offshore installations, offices, shops, hospitals, hotels, places of entertainment etc. PUWER also applies in common parts of shared buildings and temporary places of work such as construction sites. While the Regulations cover equipment used by people working from home, they DO NOT apply to domestic work in a private household.

What do the Regulations require me to do?

You must ENSURE that the work equipment you provide meets the requirements of PUWER. In doing so, you should ensure that it is:

– SUITABLE for use, and for the purpose and conditions in which it is used;

– MAINTAINED in a safe condition for use so that people’s health and safety is not at risk; and

– INSPECTED in certain circumstances to ensure that it is, and continues to be, safe for use. Any inspection should be carried out by a competent person (this could be an employee if they have the necessary competence to perform the task) and a record kept until the next inspection.

You should also ENSURE that RISKS, created by the use of the equipment, ARE ELIMINATED WHERE POSSIBLE OR CONTROLLED BY:

– taking appropriate ‘HARDWARE’ MEASURES, eg providing suitable guards, protection devices, markings and warning devices, system control devices (such as emergency stop buttons) and personal protective equipment; and

– taking appropriate ‘SOFTWARE’ MEASURES such as following safe systems of work (eg ensuring maintenance is only performed when equipment is shut down etc), and providing adequate information, instruction and training.

A combination of these measures may be necessary depending on the requirements of the work, your assessment of the risks involved, and the practicability of such measures.

You need to ENSURE that people using work equipment have received ADEQUATE TRAINING, INSTRUCTION AND INFORMATION for the particular equipment.

Health & Safety at Work Act (HASAWA)

The Health and Safety Commission (HSC) conducted a review of health and safety regulation in 1994. It found that people were confused about the differences between:

– guidance;

– Approved Codes of Practice (ACOPs); and

– regulations

and how they relate to each other.

This document aims to explain how each fits in. It is for employers and self employed people, but will be of interest to anyone who wants to know how health and safety law is meant to work.

What health and safety law requires

The basis of British health and safety law is the Health and Safety at Work etc Act 1974.

The Act sets out the general duties which employers have towards employees and members of the public, and employees have to themselves and to each other.

These duties are qualified in the Act by the principle of ‘so far as is reasonably practicable’. In other words, an employer does not have to take measures to avoid or reduce the risk if they are technically impossible or if the time, trouble or cost of the measures would be grossly disproportionate to the risk.

What the law requires here is what good management and common sense would lead employers to do anyway: that is, to look at what the risks ar e and take sensible measures to tackle them.

The Management of Health and Safety at Work Regulations 1999 (the Management Regulations) generally make more explicit what employers are required to do to manage health and safety under the Health and Safety at Work Act. Like the Act, they apply to every work activity.

The main requirement on employers is to carry out a risk assessment. Employers with five or more employees need to record the significant findings of the risk assessment.

Risk assessment should be straightforward in a simple workplace such as a typical office. It should only be complicated if it deals with serious hazards such as those on a nuclear power station, a chemical plant, laboratory or an oil rig.

The HSE leaflet Five steps to risk assessment will give you more information. Besides carrying out a risk assessment, employers also need to: make arrangements for implementing the health and safety measures identified as necessary by the risk assessment:

1. appoint competent people (often themselves or company colleagues) to help them to implement the arrangements;

2. set up emergency procedures;

3. provide clear information and training to employees;

4. work together with other employers sharing the same workplace.

Other regulations require action in response to particular hazards or in industries where hazards are particularly high. A list of the main regulations which apply generally is in Appendix 1. Many ar e not qualified by ‘reasonable practicability’.